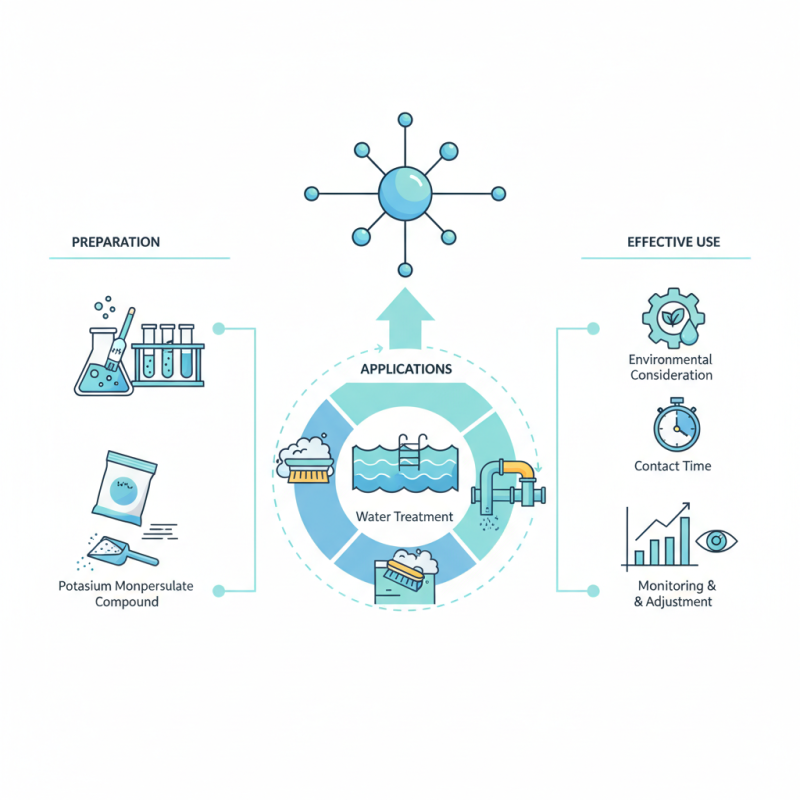

Potassium Monopersulfate Compound is a versatile oxidizing agent. It can be used in various applications, including water treatment and cleaning. Understanding how to use it effectively is essential for achieving desired results.

Using Potassium Monopersulfate Compound requires careful handling. It can produce effective oxidation without the harmful byproducts found in other chemicals. However, improper use can lead to inefficiencies. You might find it challenging to gauge the right concentration or contact time.

Consider the environment in which you are using it. Testing your water quality before treatment is crucial. Ensure that the application method matches the intended outcome. Without this, you might end up with uneven results. Regular adjustments based on observations can lead to better effectiveness in your projects.

Potassium monopersulfate is a powerful oxidizing agent. It is often used in swimming pools, spas, and wastewater treatment. This compound is known for its ability to break down organic materials, helping to keep water clean and clear.

The properties of potassium monopersulfate make it versatile. It can be used for shock treatments in pools and effectively oxidizes contaminants. Furthermore, it is safe when used correctly. Always wear gloves when handling this compound.

Tips: Always pre-dissolve potassium monopersulfate in water. This ensures even distribution in your pool. Use a test kit to measure pH and chlorine levels. Adjust these levels for optimal performance. Regular testing is key for effective sanitation; it helps prevent issues like algae growth. Be mindful of overuse. Too much can lead to skin irritations.

Potassium monopersulfate is a versatile compound widely used in water treatment. Its application in disinfection processes has gained attention due to its effectiveness against various pathogens. According to industry reports, potassium monopersulfate significantly reduces bacteria counts in municipal water systems. Studies indicate a 99% reduction in E. coli levels when treated with this compound.

In addition to disinfection, potassium monopersulfate aids in oxidation. It can effectively degrade organic pollutants, making it ideal for wastewater treatment. Treatment plants often incorporate it to improve effluent quality. Some reports show a decrease in total dissolved solids by 30% after treatment with potassium monopersulfate. However, it is essential to monitor dosages. Excess use can lead to increased chemical costs and potential water quality issues.

Proper application methods are crucial. Some facilities may underestimate the dosage needed, resulting in insufficient treatment. Others might overshoot, leading to an imbalance. Regular assessments should guide operational adjustments. Understanding specific water conditions is vital for effective use. Each application requires careful consideration to avoid inefficiencies.

When handling potassium monopersulfate, safety is key. Always wear appropriate personal protective equipment, such as gloves and goggles. This prevents skin and eye irritation.

Ensure you work in a well-ventilated area. Inhaling dust can cause respiratory issues. Keep the substance away from moisture. It reacts with water, which could lead to unwanted reactions.

Tips: Store the compound in a cool, dry place. Use airtight containers to minimize exposure to air and humidity.

Read the safety data sheet carefully before use. Understanding its properties helps prevent accidents.

Monitor your workspace for spills or leaks. If a spill occurs, clean it up immediately using appropriate methods. Do not let it sit.

Take precautions seriously; they can save you from dangerous situations. Always err on the side of caution.

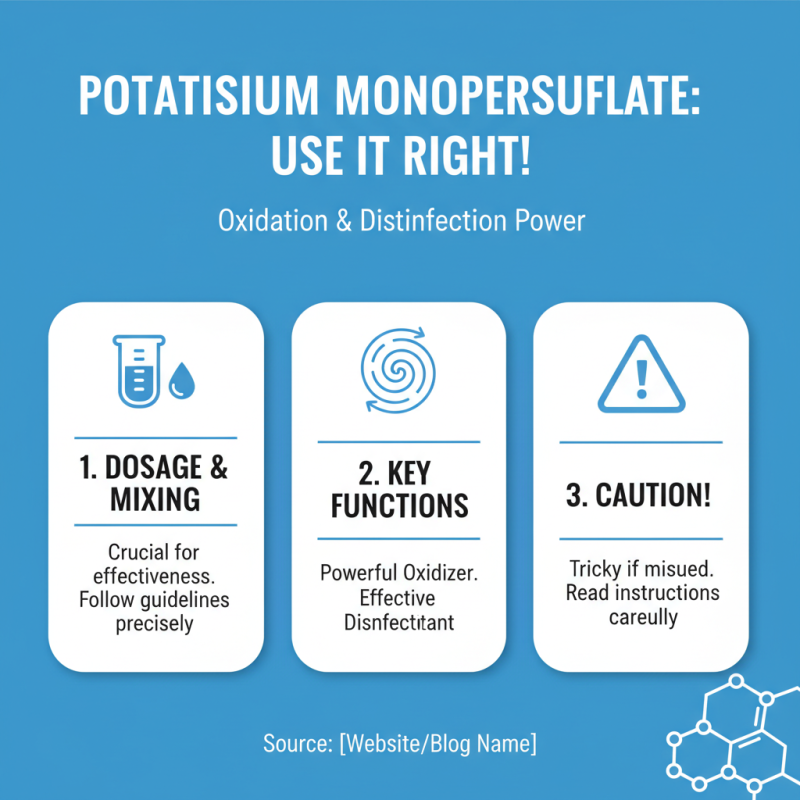

When using potassium monopersulfate, proper dosage and mixing are crucial for effectiveness. This compound works well for oxidation and disinfection. However, it can be tricky if not used correctly.

To determine the right dosage, base it on your specific need. For water treatments, a concentration of 10 to 30 grams per 1,000 liters is often effective. Adjust this based on water quality and treatment purpose. Always measure precisely. Too much can lead to residue problems or irritation.

Tips: Always wear gloves when handling the compound. It can be harsh on the skin. Mix it in a well-ventilated area, as fumes can create discomfort. Start with a small test batch before full application. This ensures compatibility with your water or surface.

Mix the compound with water carefully. Stir gently to dissolve completely. Avoid clumps since they can affect performance. Monitor the pH after mixing, as it may shift. Aim for a neutral pH for the best results. Consider how environmental factors may affect your dosage needs. Adjust as necessary and keep clear records of applications.

When using potassium monopersulfate, avoiding common pitfalls is essential. Many users underestimate the importance of precise measurements. Inaccurate dosing can lead to ineffective results. Studies indicate that over or under-application can reduce oxidizing efficiency by over 30%. Such miscalculations waste both time and resources in the long run.

Another frequent mistake is neglecting proper mixing techniques. Insufficient agitation can cause uneven distribution. This results in some areas receiving too much treatment, while others remain untreated. An industry report found that inconsistent application could reduce effectiveness by as much as 25%. Users should prioritize uniform mixing to maximize the compound's potential.

Finally, many overlook the importance of compatibility with other chemicals. Some substances can react negatively with potassium monopersulfate. This can decrease its efficacy and even create unwanted byproducts. Be cautious about mixing agents and always check compatibility guidelines. Making these common mistakes could lead to ineffective treatments and unexpected outcomes.