In poultry farming, maintaining hygiene is crucial. Chicken disinfectant plays a vital role in ensuring the health of birds. This product helps eliminate harmful pathogens that can threaten livestock. Disinfectants are designed to target viruses, bacteria, and fungi.

When used correctly, chicken disinfectants can significantly reduce disease outbreaks. They work by breaking down the cell walls of microorganisms. Proper application includes cleaning surfaces before disinfecting. It's essential to follow guidelines for effective use. However, not all products are equally effective; some may require further research and consideration.

Farmers often overlook the importance of regular disinfection practices. Relying solely on vaccinations or medications can be risky. A balanced approach is necessary for sustainable farming. Understanding the role of chicken disinfectants is vital for improving flock health.

Chicken disinfectant is a specialized solution designed to eliminate harmful pathogens in poultry farming. Its primary purpose is to maintain a healthy environment for chickens. This is crucial because chickens are susceptible to various diseases. Effective disinfection helps prevent outbreaks that could devastate a flock.

The disinfectant works by breaking down the cell walls of bacteria and viruses. This process renders them inactive, thus stopping their spread. Many options exist, including chemical solutions, heat, and steam. Each method has pros and cons, and often, a combination is necessary. Farmers must assess their specific needs before choosing a method.

In environments where biosecurity is lax, relying solely on one disinfectant may not be sufficient. Routine cleaning and disinfection should be part of a broader strategy. Farmers must remain vigilant to ensure that their practices genuinely reduce disease risk. Missteps in this crucial area can have lasting consequences.

In the poultry industry, various types of chicken disinfectants play a crucial role. These products help prevent the spread of diseases among birds. Common options include quaternary ammonium compounds and hydrogen peroxide. These disinfectants are chosen for their effectiveness against bacteria and viruses.

Quaternary ammonium compounds are popular for their ease of use. They can be sprayed or wiped on surfaces. However, they can leave residues that may require additional cleaning. Hydrogen peroxide is another effective option. It breaks down into harmless water and oxygen, making it safer for the environment.

Despite their benefits, challenges exist. Some disinfectants lose potency in the presence of organic matter, like feces. This can limit their effectiveness, especially in large poultry farms. Additionally, improper dilution can lead to inadequate disinfection. It’s essential to follow guidelines closely to ensure proper usage. Understanding these factors helps in selecting the right disinfectant for poultry operations.

| Disinfectant Type | Active Ingredient | Effectiveness | Application Method | Contact Time |

|---|---|---|---|---|

| Quaternary Ammonium Compounds | Benzalkonium Chloride | Effective against bacteria, viruses, and fungi | Spray and wipe | 10 minutes |

| Chlorine Compounds | Sodium Hypochlorite | Broad-spectrum antimicrobial activity | Soaking and spraying | 5-15 minutes |

| Acidic Detergents | Phosphoric Acid | Effective for mineral deposits and biofilms | Foaming application | 10 minutes |

| Oxidizing Agents | Hydrogen Peroxide | Effective against spores, bacteria, and viruses | Fogging and spraying | 30 minutes |

| Essential Oils | Thyme Oil | Natural antimicrobial properties | Spraying | 5-10 minutes |

Chicken disinfectants play a vital role in poultry farming. They are designed to reduce the risk of disease by targeting harmful pathogens. These disinfectants work through various mechanisms, disrupting the cellular processes of microorganisms. A study from the Poultry Science Association highlights that effective disinfectants can reduce pathogens by over 99% when used correctly.

One common method is oxidative stress. Disinfectants generate reactive oxygen species, leading to cellular damage in bacteria and viruses. This process weakens their ability to survive and reproduce. An industry report notes that using these disinfectants can lower the incidence of avian diseases significantly. However, not all disinfectants are equally effective against all pathogens.

Another mechanism involves disrupting cell membranes. Certain disinfectants can break down lipid bilayers, causing cell lysis. While this is effective, it's essential to choose the right product for specific pathogens. Some may require higher concentrations or longer contact times. A significant number of poultry farms struggle to find a balance, leading to potential inefficiencies. Understanding these mechanisms can help improve biosecurity measures in the industry, but continued research is vital.

This bar chart illustrates the effectiveness of various chicken disinfectants against common poultry pathogens. The percentages represent the reduction in pathogen levels when disinfectants are applied, showcasing their ability to enhance food safety in poultry management.

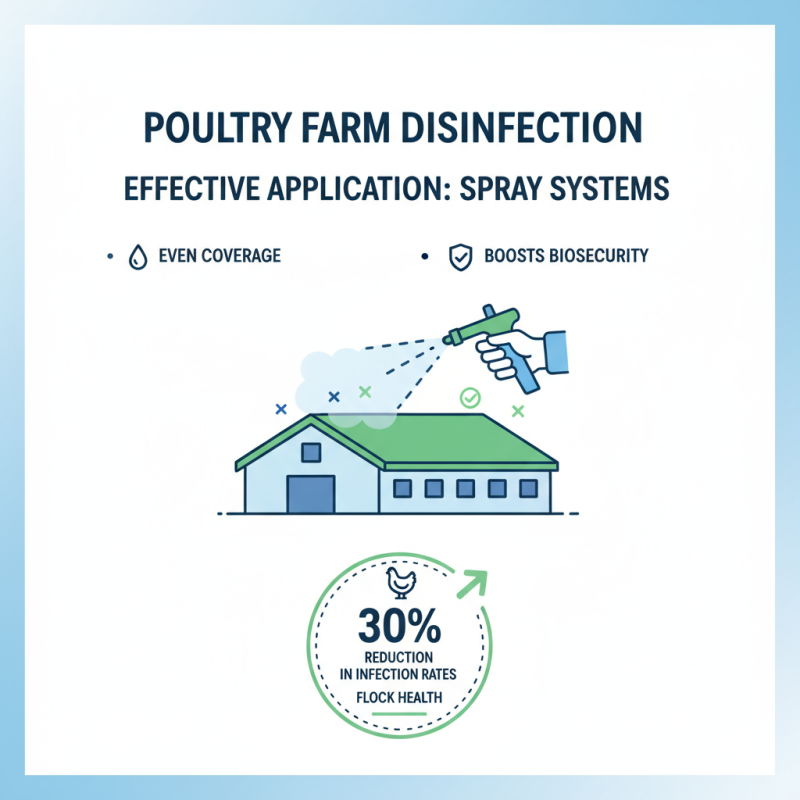

Effective application methods for chicken disinfectants are essential in poultry farms. One common approach is using spray systems. This method ensures even coverage of surfaces. It maintains biosecurity by reducing pathogens that cause diseases. According to industry reports, regular disinfection can decrease infection rates by up to 30%. This is crucial for maintaining flock health.

Another method is fogging, which uses a fine mist to disinfect larger areas. This is beneficial for hard-to-reach spots. It creates an environment less hospitable to bacteria or viruses. Studies indicate that fogging can improve sanitation in poultry houses significantly. However, this method requires careful control. Overuse can lead to residue and impact animal health.

Using foam systems is also gaining popularity. These systems allow for targeted application on vertical surfaces. Foam adheres well, maximizing contact time with the surfaces. Reports reveal that foam applications can enhance disinfection efficacy by up to 50%. However, proper training is necessary to avoid inconsistencies in application. Operators must be aware of potential gaps during the cleaning process. Regular assessment and adjustment are essential for optimal performance.

Disinfectants play a crucial role in poultry health, particularly in managing diseases. Using disinfectants improperly can lead to issues. According to a recent industry report, about 32% of poultry operations have reported ineffective cleaning due to poor disinfectant usage. This statistic highlights the need for proper training and adherence to guidelines.

When using disinfectants, safety is paramount. Operators should wear protective gear, including gloves and masks. Data shows that 54% of incidents involving disinfectants arise from inhalation or skin contact. Regulations exist to ensure that disinfectants are safe for both poultry and workers. Some formulations are only approved for specific pathogens. Understanding these details is vital for effective sanitation.

Moreover, the application of disinfectants should be monitored. Overuse can lead to resistant strains of pathogens, complicating future control efforts. A study indicated that up to 29% of farms reported increased resistance after regular disinfectant use. Operators must strike a balance between efficacy and safety. Identifying when and how to apply these agents can be challenging, but essential for maintaining a healthy flock.